Product details

Sale Creaform Metrascan 70 with Creaform C-Track 780 Dual-Camera Sensor and HandyProbe portable CMM arm-free probing system, VXelements software License, Fresh Creaform Calibration with 1 Year Creaform Warranty.

Lightly used, very well-equipped, this Creaform Metrascan 70 sale in complete set including All Controllers, FireWire cable, Targets, VXelements software License, Recalibration sphere, Calibration tools, Tripod, Carrying Case.

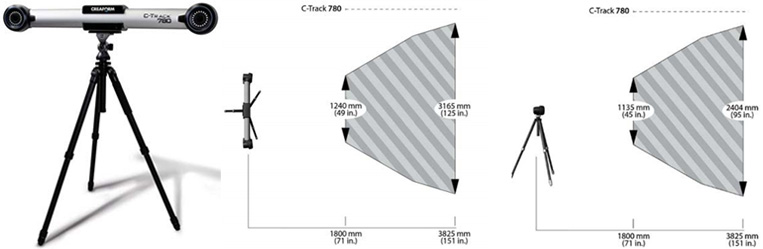

The C-Track 780 dual-camera sensor is fitted with high-quality optics and special lighting, enabling it to measure all reflectors within its operating space. In addition to tracking the reference model of the whole system, the C-Track 780 ensures the accurate localization of the MetraSCAN, and performs continuous image acquisition and transmission, lighting of reflectors, management of exchanges with the computer and storage of sensor parameters.

Creaform Metrascan | The Optical CMM 3D Scanners for Industrial Applications

The MetraSCAN 3D scanners make it possible to easily and dynamically extend the measurement volume with no loss of accuracy. Compared to other 3D scanners on articulated arms, MetraSCAN 3D scanners allow total freedom of movement for increased productivity and quality.

The Creaform MetraSCAN 70 is a professional optical coordinate measuring machine (CMM) scanning system made by Creaform, a manufacturer based in Canada. On the shop floor, the metrascan 3D outperforms scanners that are mounted on traditional portable CMMs. Because it is truly portable and insensitive to changes in the environment (e.g. parts displacement, set-up or CCM instability), It is highly efficient measuring parts that can't be move to a granite or cast iron table. Combined to the HandyPROBE CMM (included), the MetraSCAN 3D is the best solution for geometric and surface inspectionon parts ranging from 1 to 10 meters in size, no matter the type of material they are made of.

Creaform MetraSCAN 70 3-D Optical CMM scanner offers increased resolution. It is ideal for projects where geometrical feature definition is key, such as sheet metal and tooling inspection. Work with the C-Track dual-camera sensor. It is also possible to network the MetraSCAN scanners with 2 or 4 C-Track and benefit from the C-Link functionality, which drastically increases the measurement speed and ease-of-use of the system. The combination of the system with the HandyPROBE, increases the reliability, speed and versatility of the measurement process, whether for metrology or large-scale reverse engineering applications.

C-Track Dual-Camera Sensors

Creaform C-Track Dual-Camera SensorsThe C-Track dual-camera sensors are fitted with high quality optics and special lighting, enabling them to measure all reflectors within their operating space. In addition to tracking the whole system's reference model, the C-Tracks ensure the exact localization of the HandyPROBE, perform continuous image acquisition and transmission, lighting of reflectors, management of the exchanges with the computer and storage of the sensor parameters.

The MetraSCAN 3D is currently used on the production lines of major players from the automotive, aerospace and manufacturing industries.

GREATER, EXTENDABLE MEASUREMENT VOLUME : CAN BE EASILY AND DYNAMICALLY EXTENDED WITHOUT ANY LOSS OF ACCURACY AND WITHOUT ANY CONVENTIONAL LEAPFROG

GREATER, EXTENDABLE MEASUREMENT VOLUME : CAN BE EASILY AND DYNAMICALLY EXTENDED WITHOUT ANY LOSS OF ACCURACY AND WITHOUT ANY CONVENTIONAL LEAPFROG

AUTOMATIC ALIGNMENT : THE USE OF OPTICAL REFLECTORS ALLOWS SCANNING AND PROBING OF MANY IDENTICAL PARTS IN RAPID SUCCESSION. NO NEED FOR THE OPERATOR TO RE-ALIGN DATA AFTER MOVING THE PART OR THE C-Track, RESULTING IN LESS SET-UP AND ERROR ACCUMULATION MEASUREMENT OF PARTS IN PRODUCTION WITHOUT HAVING TO ALIGN EVERY PART

COMPLETE AND POWERFUL INSPECTION SOLUTION: ALLOWS GEOMETRICAL AND FREEFORM INSPECTION OR REVERSE ENGINEERING COMBINING PROBING AND SCANNING ON THE SAME SYSTEM

SCANNING AND PROBING SOLUTION FOR GEOMETRIC/SURFACE INSPECTION PARTS: RANGING FROM 1-10 m, MADE OF ANY TYPEOF MATERIAL

TRUsimplicity

- FASTER AND EASIER MEASUREMENT.

- HANDHELD ANDARM-FREE. ALLOWS THE USER TO MOVE FREELY AROUND THE PART

- USER-FRIENDLY.INTUITIVE SYSTEM WITH A VERY SHORT LEARNING CURVE

- 5-MINUTE INSTALLATION

TRUaccuracy TECHNOLOGY: HIGHLY-ACCURATEMEASUREMENTS, NO MATTERTHE MEASUREMENT ENVIRONMENT(INSTABILITY, VIBRATIONS, THERMAL VARIATIONS, ETC.) OR OPERATOR SKILLS

TRUportability: TRULY PORTABLE. INSPECTION OR REVERSE ENGINEERING OF PARTS, SUB-UNITS OR COMPLEX ASSEMBLIES WITH UNEQUALLED PRECISION, MOBILITY AND FLEXIBILITY - NO MATTER WHERE (LAB, FACTORY, OFF-SITE).

COMPATIBLE WITH ALL MAJOR SOFTWARE: INSTANT INTEGRATION INTO YOUR QC PROCESS

TRUaccuracy TECHNOLOGY: The Most Accurate Measurement Solution.

Creaform’s TRUaccuracy technology ensures highlyaccurate measurements, regardless of the measurement environment (instability, vibrations, thermal variations, etc.) or operator skills.

- With the dynamic referencingmode of the C-Track, the coordinate system can be literally ”locked” onto the part(s) being measured, thus maintaining part alignment during the entire 3D scanning process.

- With the automatic alignmentfunction, manual operation is no longer needed during the alignment phase and root cause errors are drastically reduced.

- With the fast user calibration process using a certified gauge, the MetraSCAN 3D optical CMM scanners deliver constant accuracy during its entire life cycle

- With the continuous monitoring ofparameters (temperature, accuracy, etc.), device accuracy is maintained throughout entire operation

APPLICATIONS

The MetraSCAN 3D scanner is especially useful for customers who are looking for a portable 3D measurement solution to measure length, geometric entities or surfaces. The MetraSCAN 3D works directly on the shop floor without granite or steel tables or dedicated control jigs.

The 3D measurement device reaches a measurement accuracy of 0.085 mm on parts of size ranging from 1 to 3 meters, with possible extension of up to 10 m, and made of any type of hard material.

MetraSCAN 70: The MetraSCAN 70 offers increased resolution. It is ideal for project where geometrical feature definition is key, such as sheet metal and tooling inspection

MetraSCAN 210: Because it features extended scanning surface, the MetraSCAN 210 offers increased measurement speed with equal accuracy. It is increased stand-off and depth of field make for enhanced scanning flexibility. It is ideal for large surface metrology and large-scale reverse engineering

The MetraSCAN 3D optical CMM scanners can carry out the following tasks:

Inspection and QC

- Part-to-CAD analysis

- First article inspection

- Supplier product quality inspection

- Conformity assessment of 3D models against original parts or production tooling

- Conformity assessment of manufactured parts against originals

- Alignment

- Tooling certification

Reverse Engineering

- 3D scan-to-CAD

- 3D modeling

- Tooling and jigs development

- Maintenance, repair and overhaul (MRO)

- Finite Element Analysis (FEA

THE C-Track DUAL-CAMERA SENSORS

The C-Track dual-camera sensors are fitted with high quality optics and special lighting, enabling them to measure all reflectors within their operating space. In addition to tracking the whole system's reference model, the C-Tracks ensure the exact localization of the HandyPROBE, perform continuous image acquisition and transmission, lighting of reflectors, management of the exchanges with the computer and storage of the sensor parameters.

Download Creaform Metrascan 3D Brochure